HORIZONTAL CNC MACHINING

13 ENSHU Horizontal Machining Centers

Fanuc Series 31i Control

Axis Travel – X, Y, and Z travels 23.6″ up to 31.5″

60 – 220 automatic tool changer capacity

Pallets ranging from 400mm (15.7″ x 15.7″) – 500mm (19.7″ x 19.7″)

Full 4th axis

15,000 RPM to spindle

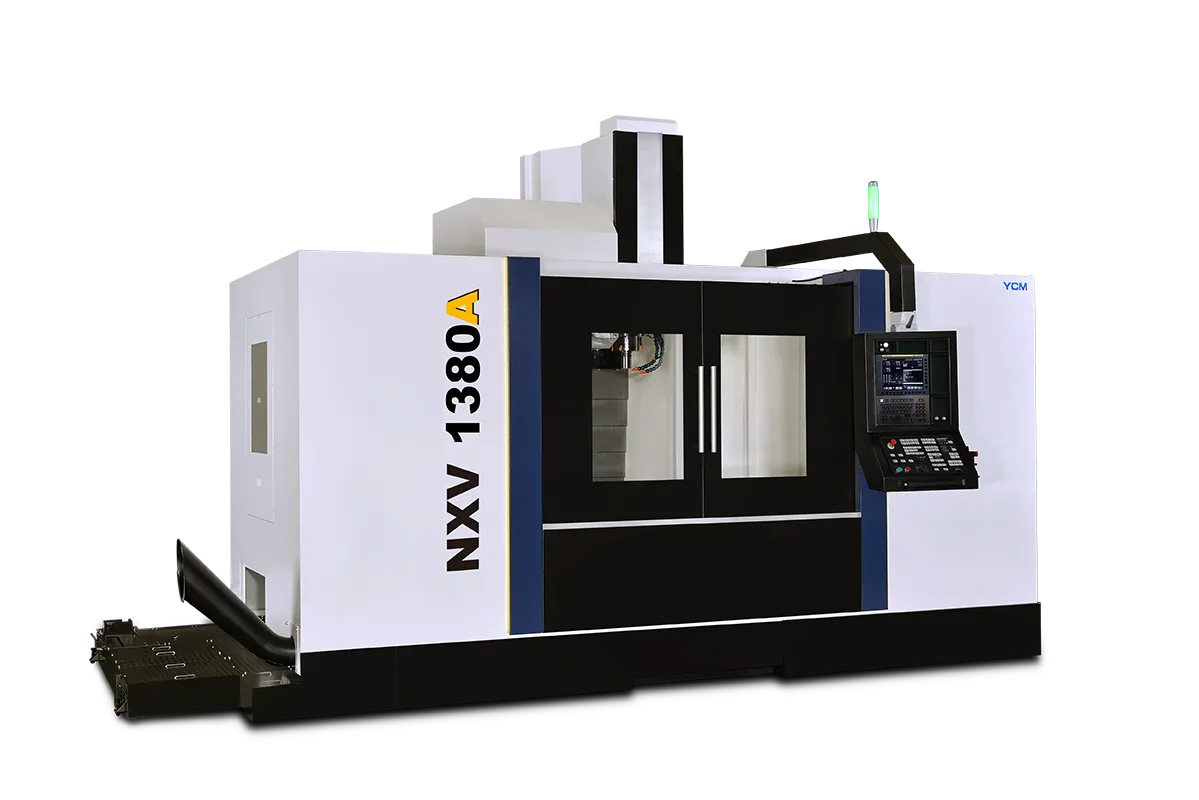

VERTICAL CNC MACHINING

Multiple Vertical CNC Machining Centers

Fanuc Series Controls

Axis Travel – X, Y, and Z travels

Tables ranging from 43.3″ x 25.6″

8,000 RMP to spindle

Live tooling

MILL / TURN MACHINING

3 Lathes

Fanuc Series Controls

Axis Travel – X, Y, and Z

Full C axis on main and sub spindle

Live tooling

Copyright © 2025

SUMMITMACHINEWORKS.COM, All Rights Reserved.