The Evolution of Manifolds: From Simple Valves to Complex Networks

The Evolution of Manifolds: From Simple Valves to Complex Networks

Introduction

Manifolds have come a long way from being basic flow control devices to becoming essential components in industrial applications. Whether in air compressors, gas distribution, or pneumatic systems, manifolds now operate as intricate networks designed for efficiency and precision. Thanks to CNC machining, the manufacturing of these components has reached a new level of accuracy and reliability. Summit Machine Works specializes in delivering high-quality CNC services to create custom manifolds that meet the demands of modern industries.

The Early Days: Simple Valves and Basic Flow Control

Originally, manifolds were nothing more than a series of valves controlling the distribution of fluids or gases. They were manually operated and lacked the complexity needed for today’s high-performance applications. These early designs were limited in precision, often leading to inefficiencies in air, gas, and pneumatic systems.

The Shift to Multi-Port Manifolds

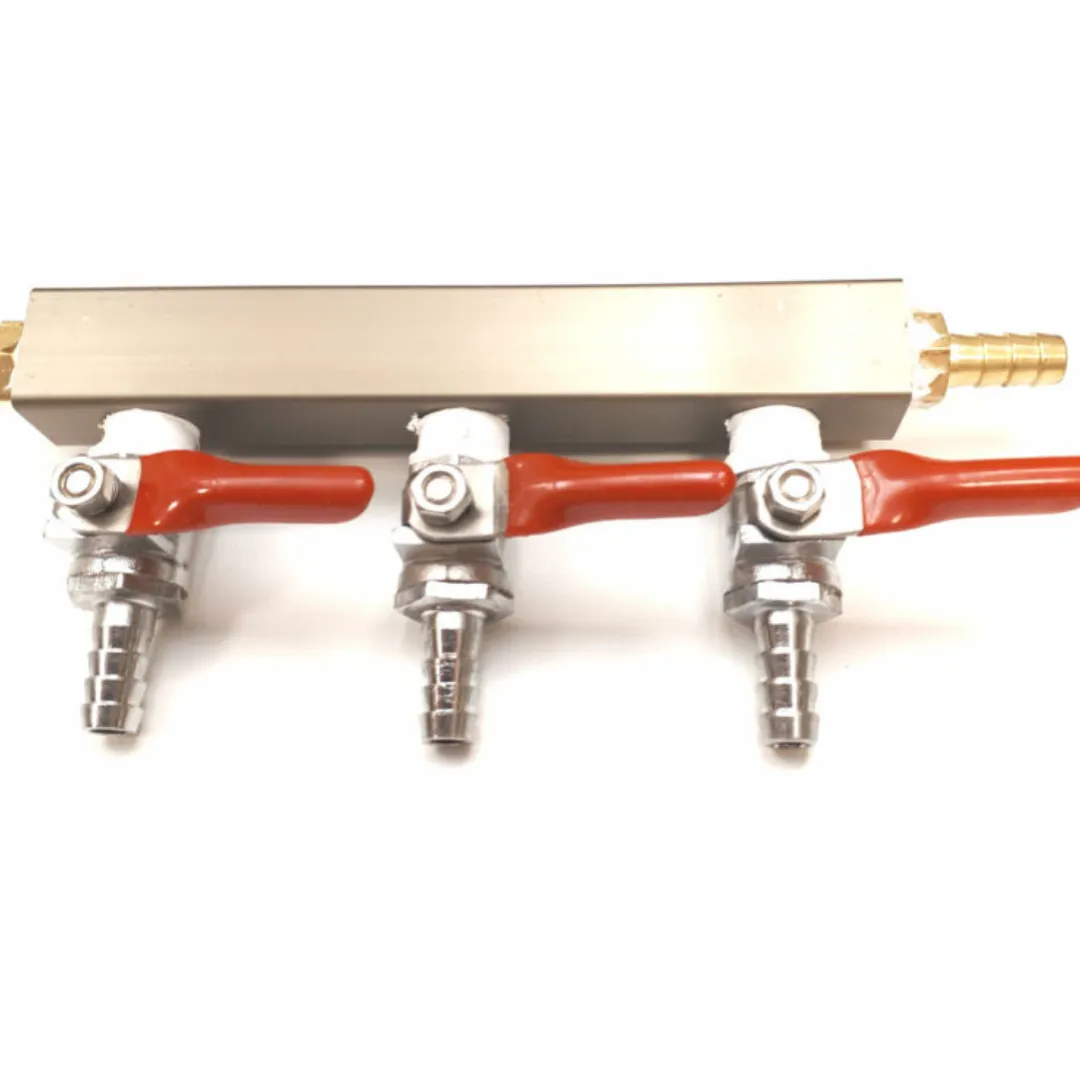

As industries grew, so did the need for more efficient flow distribution systems. The development of air compressor manifolds and multi-port designs allowed for better flow control and reduced energy loss. These advancements paved the way for automation, integrating pneumatic and gas manifolds into various industrial processes.

The CNC Revolution: Precision-Manufactured Manifolds

The introduction of CNC machining transformed manifold production. Modern CNC machines can create custom air, gas, and pneumatic manifolds with extreme precision, ensuring optimal performance in industries such as aerospace, automotive, and manufacturing. At Summit Machine Works, we utilize cutting-edge CNC technology to craft high-performance manifolds tailored to specific industry needs.

Why Choose Summit Machine Works for CNC-Manufactured Manifolds?

Expert CNC Services: We specialize in precision machining for air manifolds, gas manifolds, and pneumatic systems.

Custom Solutions: Our CNC capabilities allow us to design and produce tailored manifolds for unique applications.

Industry-Leading Quality: We ensure high standards in every CNC project, delivering manifolds that maximize efficiency and durability.

Conclusion

Manifolds have evolved from simple valve systems to highly sophisticated networks, thanks to advances in CNC machining. If you need custom manifolds with unmatched precision, Summit Machine Works is your trusted partner. Contact us today to learn how our CNC services can enhance your operations.

Explore our CNC machining solutions at Summit Machine Works.